Research and development

Industry 4.0

The plants supplied by Alpilaser are for the most part open to integration with other handling and processing systems, interface with the management system, receiving work orders and back data for the management and monitoring of production.

Planning, design and software

Another AL.PI. strong point is the special attention paid to the graphic’s elaboration and digitalization of the products, optimized by three software packages for programming and management, developed specifically for processing pipes. The drastic reduction in design and prototype construction time reduces the time taken for the development of new products to the minimum and thus saves costs.

Thanks to latest generation software packages, our qualified specialists of technical Dept. are supported and they go from the idea to the finished article with precision, speediness and creativity.

Innovative technical development with new softwares:

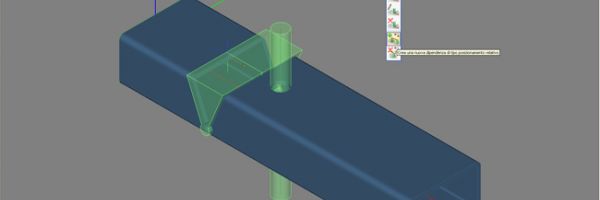

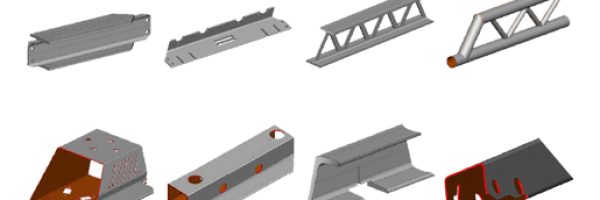

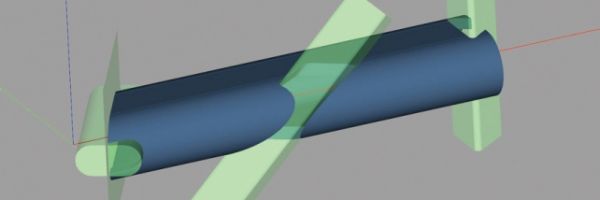

- Design of individual components – Artube Cad 3D

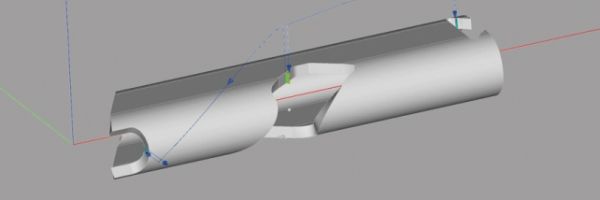

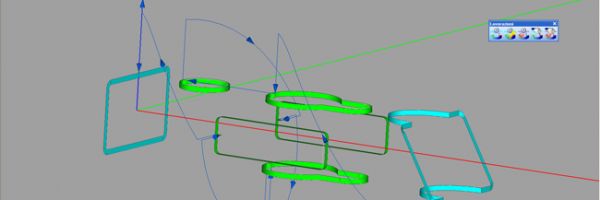

- Adopt 3D models – Artube import of File STEP+IGES

- Program generation – piece- – Artube Cam 3D

- Customize cutting strategy – Artube Cam edit advanced

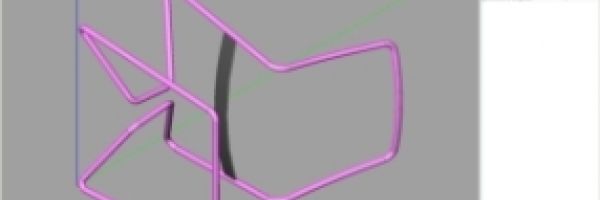

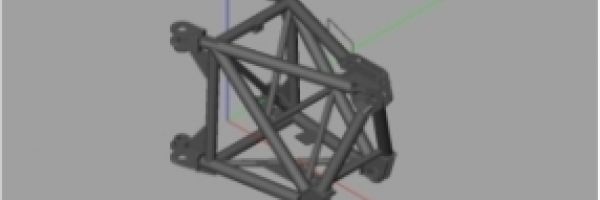

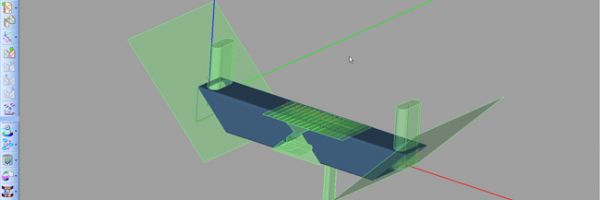

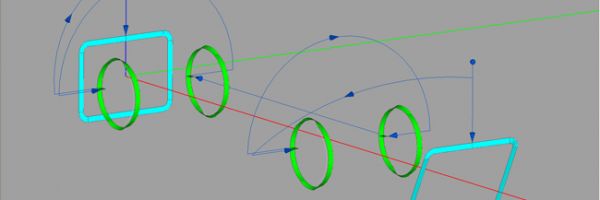

- Artube frames – draw complex shell and framework

- Design of single components, parametric 3D CAD-CAM software to design, to draw and generate the machine program for individual tubular parts. Automatic application of best technological cutting parameters. Possibility to apply different cutting strategies.

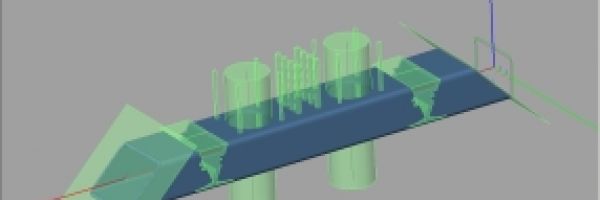

- Design of complex structures and frames using parametric 3D software automatically generating the individual components and complex structures.

- Precise and rapid generation of the joints.

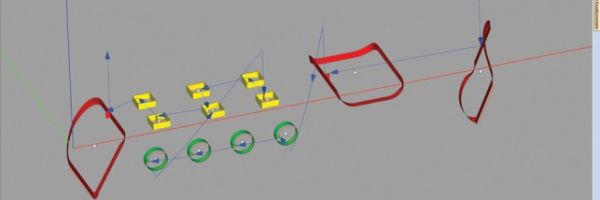

- Protube- Planning and monitoring of production phase, checking of machine state, production line batchs, commission management.

- Partviewer – dinamic simulation of pieces

- Composer – realization of simil component.